Alexis from Living Energy Farm talks more about how electricity works in off-grid situations, including his community. A continuation from Part 1 last week.

Sustainability

Renewable Electricity Workshop, Part One

Alexis from Living Energy Farm wants you to know how electricity works, particularly in the context of off grid and community living.

Living Energy Farm’s January – February 2024 Newsletter

January – February 2024 Newsletter

DC Microgrids Continue to Spread in the Caribbean

John and Debbie just returned home from three weeks in Puerto Rico. The trip was a whirlwind of installations, events, checkins with previous installations, and continuing to deepen our relationship with people and movements on the island.

We started our visit staying at Otra Cosa, a queer-friendly farm and homestead in San Salvador, home to Tara Rodriguez Besosa and Millo Huertas, two friends and organizers. Otra Cosa is off the grid and transitioning to a DC system. Tara is the cofounder of food sovereignty non-profit El Departamento de la Comida (the food department, or El Depa), which has its headquarters right down the hill from Otra Cosa, and has been our biggest organizational supporter on the island.

We installed DC equipment at El Depa a year ago, but the battery system was being underused, as the building was wired for AC florescent lighting. We could have switched out the fixtures, but the existing wiring in the walls was deemed to be unsafe for use with low voltage DC. (12VDC can build up more heat in the connections than high voltage AC, therefore weak connections can be hazardous. Badly made electrical connections, like wires twisted together with no wire nut, are disturbingly common in PR.)

Depa wanted to be able to run their lights off of their battery, so the first project of the trip consisted of building a parallel 12VDC lighting system in their Agroteca (agricultural resource center) and community kitchen.

El Depa organized the DC solar training at LEF last summer, and offered the training free of charge to participants, but required that trainees volunteer for 30 hours on an installation project. Most of our trainees did their hours during this trip.

It was great fun for us to reconnect with the folks we hosted at LEF last summer, and work on projects together. Nathania, Marielisa, Tara, Ricardo and Millo all helped with the Depa lighting system.

At our next installation at Huerto Feliz, Anacaona lent her construction skills (building a roof for the water pump), Avia took the lead with glueing PVC, and Erid, the Huerto Feliz garden manager, organized volunteers and did organizational support.

Anacaona’s roof.

Huerto Feliz is a community garden managed by Urbe Apie, a nonprofit that occupies and revitalizes abandoned spaces in downtown Caguas for housing, food production, and community enrichment. The water system we built uses rainwater collected from surrounding buildings, and will be essential for watering the garden and providing services for the community during an emergency. We also installed a direct drive fridge, and a lighting/charging system for the plaza next to the garden. As an occupied space, Huerto Feliz does not have access to grid power or city water in any reliable fashion.

Our work helped create a welcoming and comfortable space for people in the community to be able to enjoy the garden, charge their phones, get water, and store food. Extra thanks to Sunflower, a Twin Oaks member who traveled with us and was a huge help with the installation.

In addition to the new installations at El Depa and Huerto Feliz, we were able to check in with a few of the installations from last year. We made some upgrades to the system at Miguel and Dinorah’s, the elder coconut farmers in Arroyo. We added a vacuum breaker to improve the performance of their pump, and added a bathroom light to their 12V battery system. We visited Finca la Lluvia, a farm in Maricao that is home to writer and activist Aurora Levins Morales. We installed a direct drive fridge last year, and this year we added a 100AH battery kit to the system, to power a CPAP machine.

One of the goals of the trip was to set up an equipment distribution site so our trainees on the island could continue to do installations after we left. We bought a storage container, and parked it at the farm of Ricardo Martinez, who owns and operates a solar company, Energiza PR. Going forward, Ricardo will be distributing and installing for Living Energy Lights, along with Millo Huertas, Eva Campbell and our other trainees.

Our next visit to Puerto Rico is tentatively scheduled for this November, when we’ll do our third annual DC solar training/immersion. This year, instead of hosting the training at LEF, the training will be held at El Departamento de la Comida.

The goal is to make the training more accessible for Puerto Ricans who are not able to take two weeks off from work to be able to attend a program in the US. Now that Depa has a very developed DC Microgrid, we believe that the “immersion” part of training (allowing participants to spend time surrounded by and using the DC equipment) can be done as effectively in PR as in Virginia. It’s exciting progress. The recognition of the effectiveness of direct drive is growing in Puerto Rico. For individual users, it’s simply a cheaper, more durable form of solar. If we can get the use of direct drive to grow to a larger scale, then there would be no need for coal, natural gas, nuclear, or industrial “renewable” energy systems to support grid power.

Simple Harvester

Prototype 3 of the Simple Harvester is complete. We put prototype 2 in the field last year and achieved “proof of concept.” That said, prototype 3 is a huge improvement. It is a combine harvester that can harvest many different kinds of grain. It has one belt and eight turning shafts. It could probably be mass produced for around $1,000 USD. It’s very simple to operate and maintain.

There is a dire need for the Simple Harvester all over the world. And our machine works. It’s not just a theory or an idea. Small farmers in the U.S. can use old harvesters. But that’s not a solution for small farmers in Latin America, Africa, or Asia. BCS is an Italian company that makes two wheeled tractor tractors that are used by many small farmers. Their harvesting setup is $32,000 retail in the U.S. The Chinese make small combines, but they are complex and expensive. They are around $10,000 USD by the time you deal with import fees and what not.

We have a contract with the University of Missouri and the Soybean Innovation Lab to help small shops start producing Simple Harvesters in Africa. We are moving forward with that.

We have no interest in squeezing money out of African farmers. But if someone in the U.S. or Europe is going to make Simple Harvesters, or mass producers are going to make them, we want a share of the proceeds so we can fund the expansion of the conservationist design we have developed at LEF. Right now that means struggling with a pile of petty legalisms surrounding the patent. Wish us luck.

Simple Washer

David has been hard at work for a few months designing and building a control system for our Simple Washer. And now it’s working! We have used a cement mixer for years to wash clothes. It is not a lot of fun to use and not popular. The Simple Washer uses a rotating drum (like a cement mixer), but has a circuit that controls rotation. It drains through an Archimedes Screw. The Simple Washer is DC, direct drive powered. It does have a small rechargeable battery to run the electronic timing circuit. It’s not fully automated. You have to add the water from a hose. But beyond that, it runs through its wash cycle, and then drains. Then you can refill and run it again, and then it’s done.

It’s a very simple, elegant machine. It needs a bit of tweaking, but we have started using it to wash clothes, and it is certainly an improvement over the cement mixer. While there are many washing machines in the world, the DC models made in China are not very durable (as far as we know). The AC models are not easily converted, and many of those are not durable or repairable. The Simple Washer so far is a homestead model, something you would use outdoors probably. But it’s great to be making progress. We have an excellent crew at LEF these days. We are pleased David has made this work!

Biogas

We do most of our cooking at LEF with Insulated Solar Electric Cookers (ISECs). While simple solar thermal cookers (like Sun Ovens) seem like a good idea, they are very limited. The ISECs work great, and biogas is an excellent compliment to ISECs. We cook breakfast every morning with biogas. Two years ago we put a large, 2000 gallon digester into operation. We couldn’t keep it warm enough, so we added more solar thermal panels. Then last winter (over a year ago) rats got into the straw and messed up some pipes. We put the digester back on its feet. Then last summer we overheated it. We put in a thermal sink and got it going again.

Then this winter we realized we had a leak in our solar heating system. We used stainless heat exchange coils inside the digester. It is an acidic environment in there. Copper coils would not hold up. One of the compression fittings we used on the stainless failed. So we tunneled under the straw and put in expensive “swagelok” fittings, and restarted yet again. With each one of these restarts, the archae culture in the tank dies back. At best it takes weeks to get it back to a healthy state.

Cooking year round in a temperate climate with 100% renewable energy is challenging. Rocket stoves are efficient, but annoying to start. And they smoke and leave soot all over everything.

Before ISECS, we did maybe 5% of our cooking solar on a year-round basis. Now its over 70% with the ISECs. We are hoping that we can cover the other 30% with biogas and not use rocket stoves any more. But temperate climate biogas is no small project. In the future, industrial output is going to decline. That is as inevitable as gravity. Based on our lessons at LEF, if you don’t want to cook over a smoky fire, future generations are going to have to manage cooking fuel on a community scale. Even at LEF, after years of trying to find a not-smoky way to cook, we are still working on it. The digester is — hopefully — in a state where we can manage it, keep it warm enough but not too warm, year round.

But we do not as yet have a year-round feed supply for it. That is going to involve taking leaves, straw, or whatever we can get our hands on, and pre-digesting it in compost piles to a half digested state, and then feeding it into the digester. It’s coming along, but cooking with clean, renewable energy has proven challenging.

Farming

We are preparing for farming season this year. We got a large pile of leaves from a local landscaper over the winter, so we will be doing some sheet mulch gardening. We will be growing a familiar variety of seed and food crops. Otto is managing the kitchen gardens. (He also takes care of Seymour, the biogas digester.) So far this year the late winter/ spring weather has been closer to “normal,” a word which has largely lost its meaning in the age of climate change. We will see how the spring progresses.

The kids have been getting a bit more involved in farm, shop, and kitchen work, though as with all kids they like their electronic (solar powered) gizmos. We do a shop class with the kids once a week. They have been reviving a woodgas system for use on a small tractor. Our hope is to be able to start a tractor on biogas, and then run it on woodgas. We may start trying to integrate that into our farming this season as time allows. Currently, we are fully energy independent apart from a modest amount of fossil fuel (about 30 gallons) that we use for a season of farming. We are hoping that in the next couple of years we can be done using fossil fuel for the tractors as well as firewood for cooking.

We remain amused the extent to which others seem to see our life as some kind of deprivation, or something they could never do, or something they do not know how to start doing. We have a good life, and we feel like our model is a huge improvement over spending huge amounts of money bulldozing forests to build industrial solar fields. Please support us if you can.

Living Energy Farm is a project to build a demonstration farm, community, and education center in Louisa County that uses no fossil fuels. For more information see our website http://www.livingenergyfarm.org, or contact us at livingenergyfarm@gmail.com or Living Energy Farm, 1022 Bibb Store Rd, Louisa VA, 23093. Donations to the Living Energy Farm Institute are tax deductible. To make tax deductible donations, do not go to the Virginia Organizing website, go here instead: https://donatenow.networkforgood.org/1388125

Make sure to designate your donation for Living Energy Institute.

Articles and videos about LEF:

Low-Tech Magazine (based in France) did an lengthy, well-researched article, largely about LEF, entitled Direct Solar Power: Off-Grid Without Batteries. It’s at https://solar.lowtechmagazine.com/2023/08/direct-solar-power-off-grid-without-batteries/

That article talks a lot about optimal utilization, translate “community is the magic bullet that makes renewable energy work.”

Matt Dhillon at Cville Weekly did one of the best brief summaries of LEF we have ever seen. The article is entitled Power Shift, Award-winning Living Energy Farm Makes Living Off-grid Sustainable. It is at https://www.c-ville.com/power-shift

Truthdig did an article on LEF by Megan McGee, an excellent review of our work in Puerto Rico. It is entitled Decolonizing Puerto Rico Through Solar Power. It’s at

https://www.truthdig.com/articles/decolonizing-puerto-rico-through-solar-power/

We continue to post new videos on Youtube. The latest is Solar Power Systems That Last Forever, focused on our solar powered kitchen. See https://youtu.be/6XiHClx8d2Q

How to Never Pay an Electric Bill

https://www.youtube.com/watch?v=N5Wk7inoIxI&t=201s

This video is a walk-through of our energy systems at Living Energy Farm. It is a concise summary of how these systems work, and why they are not in common use already.

Solar Installations In The Navajo (Dine’) And Hopi Reservations, March 2020

http://livingenergyfarm.org/solar-installations-2020/

This is a photo essay about our project to bring durable solar energy systems to the Dine’ and Hopi Reservations, where thousands of people live without grid power involuntarily.

Support Living Energy Farm’s Climate Justice Campaign, and Bring DC Microgrids to People Who Need Them

http://livingenergyfarm.org/support-our-climate-justice-campaign/

This is an updated web page describing our broader social justice ambitions.

How to Live Without Fossil Fuel (Introductory Video) https://www.youtube.com/watch?v=Ri2U6u8p65E

Powering a Community with Solar Electricity (LEF has the only DC powered community that we know of, here’s how it works) https://www.youtube.com/watch?v=FvdExgvHnRI&t=23s

The Best Way to Store Off-Grid Energy https://www.youtube.com/watch?v=2wOxQ3sL9zc

Batteries that Last (almost) Forever https://www.youtube.com/watch?v=dfrgLsyFs0E

Virginia Homegrown created a program at LEF (the LEF part starts at the 29 minute mark in the program) https://www.youtube.com/watch?v=MDGP0C9MIzU

International Permaculture has done 2 articles on LEF. One is in issue #93, Autumn 2017, and the second is in issue #94, Winter 2017. See https://www.permaculture.co.uk/

Article about LEF at the Atlantic Online Magazine

https://www.theatlantic.com/politics/archive/2017/01/anarchism-intentional-communities-trump/513086/

Article about LEF in The Central Virginian

http://www.livingenergyfarm.org/cvarticle.pdf

LEF on CNN

http://www.cnn.com/interactive/2015/09/us/communes-american-story/

Cville weekly in Charlottesville VA

http://www.c-ville.com/off-grid-model-environmentalism-made-easy/#.VcHobF054yo

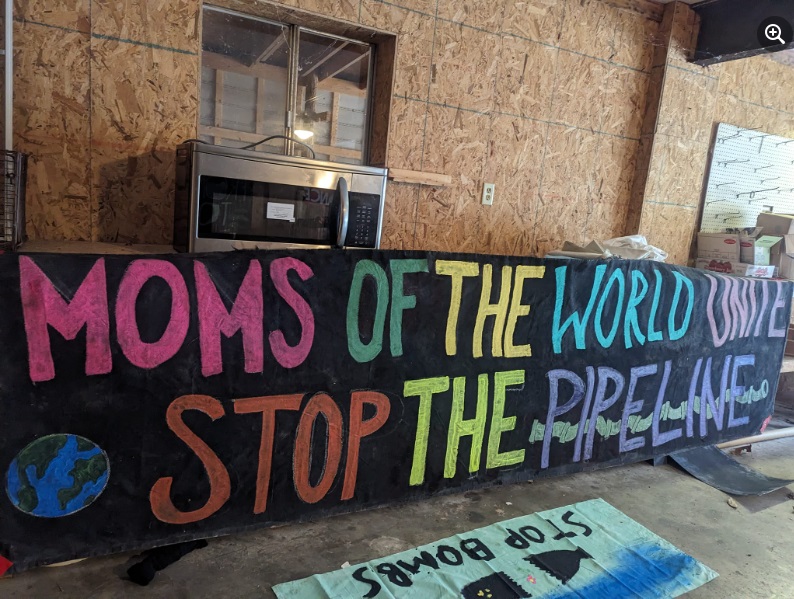

Stopping the Mountain Valley Pipeline

Serenity Solidarity wrote: “We went out for a week to support the incredible activists who have been dedicated to stopping the Mountain Valley Pipeline for 9 years. “

Forest, Peanuts, Hoop House, Lettuce, and Concert

by Raven

Once again, here is a catch up on our posts from last month on Facebook, most of which are re-posts from stuff on the various Facebook, Instagram, and website pages of the communes.

Twin Oaks posted about forest care.

This did pretty well on our Facebook feed, with ten Likes, two Loves, and a hundred and eighty views.

East Wind hadn’t been posting much on their Facebook feed so I went over to their business page and found this educational/sales piece on peanuts.

Here’s a link so you can read the original article.

This didn’t do great. It got three Likes, two Loves, but only eighty-five views.

They have a hoop house at Twin Oaks that keeps them supplied with winter produce.

This did okay, with five Likes, three Loves, and over a hundred and twenty views.

Then Glomus/East Brook Farm posted a lovely picture of Rachael by the lettuce.

This did pretty well on FB, with six Likes, four Loves, one Wow, and over a hundred and forty views.

Finally, Acorn posted this picture on their Instagram account with only a “happy new years” message on it. I am assuming it was a New Year’s concert pic.

This did okay, with four Likes, two Loves, and just over a hundred views.

Membership, Art, Water, and a Question

by Raven

Here’s this weeks sample of stuff from our Facebook feed. As usual, there is a significant time delay. These are from the middle of January.

I’m sure some of our Commune Life readers are interested in how someone joins one of these communities. After Twin Oaks posted a link to their membership process, I republished the link on our Facebook feed.

Here’s the actual link to the Twin Oaks membership page.

This did pretty well on Facebook with eleven likes, two loves, and over a hundred and seventy views.

After this, looking for something I could post from East Wind, I found their membership process and published a link to it the next day.

Here’s the actual link to East Wind’s membership process.

This did a little better than Twin Oaks, with eight likes, three loves, and over a hundred and eighty views.

Acorn published a drawing from deceased member Curt (that I misspelled Kurt).

This also did well, with four likes, two loves, and five cares (and, yes, that doesn’t add up to twelve but that’s what Facebook keeps telling me), and over a hundred and thirty views.

Glomus Commune/East Brook Community Farm is having some work done to increase their water supply and irrigation capacity.

This post did okay with three likes, a love, and a hundred and two views.

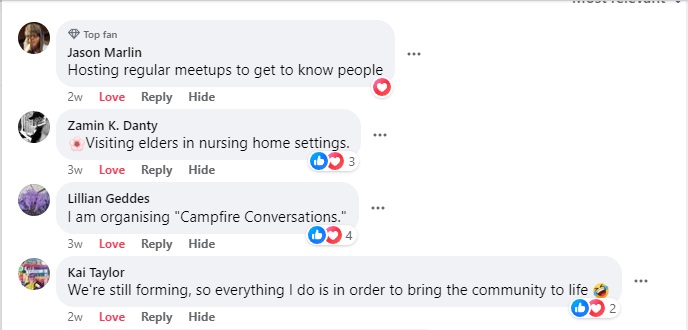

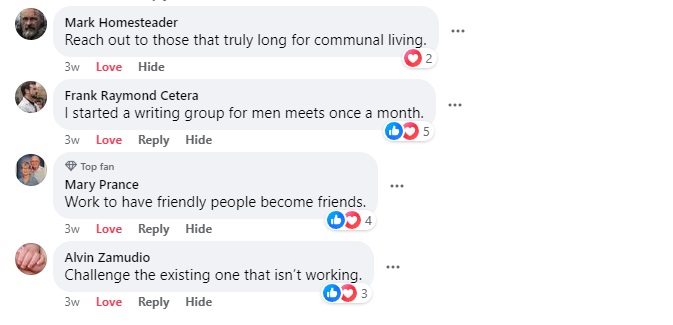

Finally, I have started putting questions on Facebook again. It’s a great way to engage viewers and it really drives up the number of views. I thought that I would start the year with this question:

Surprisingly, there were only eight comments, but I thought that they were good ones.

While there were only eight comments, it got nine likes, four loves, a share, and four hundred and forty-four views. As I said, these questions generate a lot of views.

Indigenous Walk, Baby Shower, Harvest Feast

by Raven

Finishing off the first weeks of January on Facebook.

The Serenity Solidarity folks advertised this event and said they would be there.

It sounds like a worthy cause but it didn’t do well on Facebook. It got two likes but only sixty-six views.

Meanwhile, Acorn was celebrating an impending birth.

With all those pictures and a baby coming, too, this post did well enough on Facebook. Honestly, I would have expected it to do better, but five likes, two loves, and a hundred and forty-four views is not bad.

Finally, although Twin Oaks celebrates the American Thanksgiving as a Day of Mourning, they also do celebrate a day for gratitude and the harvest.

With just one picture of a table full of sweets, this actually did better than Acorn’s baby shower, with sixteen likes and loves and a hundred and fifty-three views.

LEF November-December 2023

Living Energy Farm

November – December 2023 Newsletter

DC Microgrids in the Caribbean

As we head to press, a crew from El Departamento de la Comida, including our trainees Millo, Ricardo, Eva, and Marielisa, are in Jamaica building a DC Microgrid at Solidarity Yaad Farm. The system includes a direct drive pump, fridge, and a few 12V battery kits. Electrically, everything went smoothly, and is working great. The plumbing side of things has been more of a challenge for the crew, but they are getting close to finished with the water system as well.

Back at LEF, we’ve been hard at work building nickel iron battery boxes and making preparations for another trip to Puerto Rico. Debbie and John will be heading down there in mid-February. In addition to continuing our promotional and educational work with El Depa and Fundación Bucarabon, we’re excited to start a collaboration with Ricardo Martinez and his solar distribution company, Energiza PR.

We’ve set up a storage container at Ricardo’s farm, and now that we have a trained crew of installers on the island, we’ll be able to ship and install DC equipment in Puerto Rico at any time. We even have a Spanish website and catalog, which you can check out here:

https://livingenergylights.com/living-energy-lights-en-puerto-rico/

Ricardo, Millo, and Marielisa from Puerto Rico helping out installing direct drive solar DC equipment in Jamaica.

Eva and the Jamaican crew installing the solar pump we sent.

In other news, Alexis did an interview with an online publication Socialist News and Views. The interview is about the Simple Harvester and his book Integrated Activism. It can be heard here

Jamaica.

Technology Development at LEF

When we conceived of LEF in the beginning, we were clear that we were not going to be a technology development project. That takes too much time and money, so we thought. But that was before the Direct Drive DC Microgrid, before the Simple Harvester, before the realization that we could not obtain a lot of what we needed for a food and energy self sufficient community. At this point, we are very much a technology development project. And we are trying, with such resources as are at our disposal, to make simple, durable technologies available so working class people can use them. Of course, our big inventions are the Direct Drive DC Microgrid and the Simple Harvester. But the list of smaller inventions includes:

Direct drive, DC washing machine. Simple and effective.

A) Simple Washer

David, with support from John and Alexis, has taken over the development of the Simple Washer — a solar, direct drive washing machine. The machine uses a single tilted drum, a heavy DC gearmotor (normally used for intermediate electric vehicles like rickshaws, low speed cargo trucks or trikes). The Simple Washer uses an Archimedes screw to drain. It’s a very repairable and durable machine compared to other washers. We like it that way.

The current prototype is a more of an outdoor, homesteader model. We will make an indoor model next. We are using our current prototype to wash clothes. The mechanical side is working well.

David is still working on figuring out the best timer setup for sequencing rotation. It’s a bit tricky with floating, high voltage DC to do that, and keep it cheap and durable, but he is making great progress. See photo.

direct drive DC.

B) Direct Drive Dehydrator

The ability to dehydrate food is a critical energy need for anyone interested in food security. At LEF, we have a large solar hot air collector on the roof of our kitchen. In the winter, we blow the heated air under the floor for space heating; in the summer, we blow the heated air into a closet to dehydrate food. It works great for us, but it’s expensive and complicated to build, especially in the tropics where space heating is not needed. Looking for a more affordable, mass marketable solution, Debbie has been working on converting small, fully electric food dehydrators to 90V direct drive DC.

The dehydrators have a heating element. That can run 90V DC no problem. They have a thermostat to prevent overheating. We have found that we can use snubbers (capacitors) on AC thermostats to prevent arcing when using DC. For now at least, that seems to be working great. The dehydrators also need a fan. Small, high voltage DC fans are not so easy to find. Low voltage DC fans are widely available for electronics cooling, and the availability of buck circuits to drop DC voltage has greatly increased, so Debbie is using a buck circuit to power a low voltage fan. Electrically, it all works. Debbie is still testing to see how effectively it dehydrates food.

numbers) and kettle for

providing on-demand hot

beverages.

C) Electronic Load Diverter

Mostly we use all the watts our solar panels generate. But not quite! To provide us with convenient hot water for tea and coffee on sunny days, John set up a diversion circuit from our battery charging solar PV panel that first charges the batteries to a particular level and then diverts energy into a 24V electric thermos. It works well.

D) Solar Cookers and Hot Plates

We continue to develop our Insulated Solar Electric Cookers (which are highly efficient). We have also realized that by putting snubbers on the thermostat of a regular hot plate, we can create a simple conversion of ordinary hot plates to DC (not super efficient, but cheap and easy).

capacitor. With that installed inside this angle grinder, we can run straight off of PV

power, no external switching needed.

E) Shop Tools with Snubbers

We have also realized we can put snubbers inside shop tools. Any tool or appliance that you can carry around probably has a universal motor, and 90% of those will run daylight drive. We had been using heavy external switches, but the snubbers are small enough we can put them right in the tool and use them straight DC. Very cool.

F) Grinder for Biogas

This one we built a year or two ago. It’s a homemade, hand powered grinder for crushing material to feed the biogas. Very simple and effective.

G) Biogas Slurry Pump

Our biogas slurry pump is unique so far as we know. It’s a piston pump in which both the piston and the sleeve around the piston move independently to create a pumping action for heavy, fibrous material being pumped into the biogas digester. Instead of trying to suck material through an intake valve (as would happen on any other piston pump), the cylinder around the piston lifts up and then chops into the material in the holding tank. Then the piston pushes the material out. It will handle coarse, fibrous material in a way that no other pump will (that we know of…).

H) Squash Guillotine

So maybe this one is only of interest to seed growers, but cutting up lots of winter squash using a kitchen knife is dangerous. This is a simple device using a brush ax that allows us to cut lots of squash quickly and safely.

bourgeois squash…. or something

like that…

I) Battery Waterer

We like nickel iron batteries because they can last a lifetime. But you do have to put distilled water in them about once a month. We have had a problem with the battery kits we have been distributing in that the water level needs to be just right — about an inch from the top of the battery. How do you pour water into a battery and make it stop at just the right level, especially when the battery is in a battery box and you cannotsee the side of the battery to see the water level? Sometimes people would over-fill their batteries and spill electrolyte, which is messy. We invented a solution. We took a juice bottle, and drilled two holes in the cap. A long straw and a short straw are pushed through the holes and sealed with hot glue. Both straws protrude from the bottle top exactly one inch — the right level for watering the batteries when the bottle is inverted and the straws are inserted into the top of a nickel iron battery. The short straw goes through the lid of the bottle and stops. Water flows through this straw. The long straw goes down (up when the bottle is inverted) to the bottom of the bottle. Air flows up this straw. When the water level inside the battery reaches the level of both straws, the air flow is stopped. The bottle is “air locked.” Exactly the right level of water delivery is achieved. The battery waterer works well and costs very little to build.

J) Woodgas

Realizing how difficult it is going to be to make enough biogas to run our tractors, we have returned to working on woodgas. The shop class each week for the kids has been working to revive the woodgas reactor we put together some years ago. We have mixed feelings about woodgas. It’s smoky (on the startup) and encourages people to cut down trees. But running a machine through a field is not easy. The current thinking is to start a tractor on biogas and then run it on woodgas. (Starting a cold engine on woodgas is not easy.) We will see how it all works out.

Simplified Combine Harvester

The Simple Harvester has been Alexis’ primary focus for the last couple of months. It’s coming along. The current iteration is much sturdier, much more precise than the last one. The University of Missouri is supporting us, which is great. The expenses related to the international patent have proven larger than anticipated. It’s not clear at this time what course we will take in the long run. We have a contract with the Soybean Innovation Lab to help farmers in Africa build Simple Harvesters. Beyond that, we just don’t know. At this point, the next iteration should be operational in a couple of months. We have intentionally left some cover crop and weeds un-mowed from last summer so we can take the Simple Harvester through it to test cutting and material flow. We have two years from the date of the international patent to file for national and regional patents. We may or may not take that route. For now we just want to make the machine field ready.

We are very excited about the current iteration of the machine. It has one belt and about a dozen bearings. It could be build in small fabrication shops all over the world. It could be a big help to small farmers.

Farming

We are just finishing up the last of the 2023’s fresh persimmons. The Rosseyankas last through much of the winter. We keep them outdoors, on the porch. The biggest issue is keeping the rodents out of them. We are swapping around farm equipment to be able to run our farm on small tractor(s) using some form of renewable energy. The historic Farmall Cub tractor has an excellent, fuel efficient engine, but the original models were too top heavy. We found a Cub 154 which is much more sure-footed (lower to the ground) with a three point hitch for pulling modern implements. We have rebuilt the drive shaft to stand up to pulling discs and plows. The plan is to use one small tractor for tillage and a second tractor for cultivating. This should be a highly fuel efficient approach to running our small farm.

We’re starting to plan for next year’s seed crops, which will include watermelon (of course), squash, muskmelons, okra and tomatoes. We have invested in some modest peanut processing equipment. Peanuts are great for being a high calorie, oil and protein rich self sufficiency crop (and good money for seeds). Birds eat sunflowers, but with peanuts we can fence out the deer and make a good crop. We found a very cheap little peanut stripper for a whopping $22 that can make picking the peanuts much faster (item 134802737045 on ebay). We also picked up a very cheap peanut digger from China that someone had purchased and never used.

Interest in our project continues to grow. There are many projects in many locales with which we are consulting about building durable renewable energy systems. Please support us if you can.

Living Energy Farm is a project to build a demonstration farm, community, and education center in Louisa County that uses no fossil fuels. For more information see our website http://www.livingenergyfarm.org, or contact us at livingenergyfarm@gmail.com or Living Energy Farm, 1022 Bibb Store Rd, Louisa VA, 23093. Donations to the Living Energy Farm Institute are tax deductible. To make tax deductible donations, do not go to the Virginia Organizing website, go here instead: https://donatenow.networkforgood.org/1388125 Make sure to designate your donation for Living Energy Institute.

Articles and videos about LEF:

Low-Tech Magazine (based in France) did an lengthy, well-researched article, largely about LEF, entitled Direct Solar Power: Off-Grid Without Batteries. It’s at https://solar.lowtechmagazine.com/2023/08/ direct-solar-power-off-grid-without-batteries/ That article talks a lot about optimal utilization, translate “community is the magic bullet that makes renewable energy work.”

Matt Dhillon at Cville Weekly did one of the best brief summaries of LEF we have ever seen. The article is entitled Power Shift, Award-winning Living Energy Farm Makes Living Off-grid Sustainable. It is at https://www.c-ville.com/power-shift

Truthdig did an article on LEF by Megan McGee, an excellent review of our work in Puerto Rico. It is entitled Decolonizing Puerto Rico Through Solar Power. It’s at

https://www.truthdig.com/articles/decolonizing-puerto-rico-through-solar-power/

We continue to post new videos on Youtube. The latest is Solar Power Systems That Last Forever, focused on our solar powered kitchen. See https://youtu.be/6XiHClx8d2Q

How to Never Pay an Electric Bill

https://www.youtube.com/watch?v=N5Wk7inoIxI&t=201s

This video is a walk-through of our energy systems at Living Energy Farm. It is a concise summary of how these systems work, and why they are not in common use already.

Solar Installations In The Navajo (Dine’) And Hopi Reservations, March 2020

http://livingenergyfarm.org/solar-installations-2020/

This is a photo essay about our project to bring durable solar energy systems to the Dine’ and Hopi Reservations, where thousands of people live without grid power involuntarily.

Support Living Energy Farm’s Climate Justice Campaign, and Bring DC Microgrids to People Who Need Them

http://livingenergyfarm.org/support-our-climate-justice-campaign/

This is an updated web page describing our broader social justice ambitions.

How to Live Without Fossil Fuel (Introductory Video) https://www.youtube.com/watch?v=Ri2U6u8p65E

Powering a Community with Solar Electricity (LEF has the only DC powered community that we know of, here’s how it works) https://www.youtube.com/watch?v=FvdExgvHnRI&t=23s

The Best Way to Store Off-Grid Energy https://www.youtube.com/watch?v=2wOxQ3sL9zc

Batteries that Last (almost) Forever https://www.youtube.com/watch?v=dfrgLsyFs0E

Virginia Homegrown created a program at LEF (the LEF part starts at the 29 minute mark in the program) https://www.youtube.com/watch?v=MDGP0C9MIzU

International Permaculture has done 2 articles on LEF. One is in issue #93, Autumn 2017, and the second is in issue #94, Winter 2017. See https://www.permaculture.co.uk/

Article about LEF at the Atlantic Online Magazine

https://www.theatlantic.com/politics/archive/2017/01/anarchism-intentional-communities-trump/513086/

Article about LEF in The Central Virginian

http://www.livingenergyfarm.org/cvarticle.pdf

LEF on CNN

http://www.cnn.com/interactive/2015/09/us/communes-american-story/

Cville weekly in Charlottesville VA

http://www.c-ville.com/off-grid-model-environmentalism-made-easy/#.VcHobF054yo

How to Never Pay an Electric Bill

Alexis shows off Living Energy Farm and demonstrates how to live off-grid.

LEF: Solar Forever

Alexis from Living Energy Farm talks about how to have solar power for life.